The refinement of cold-rolled steel strips has been our passion for more than 120 years.

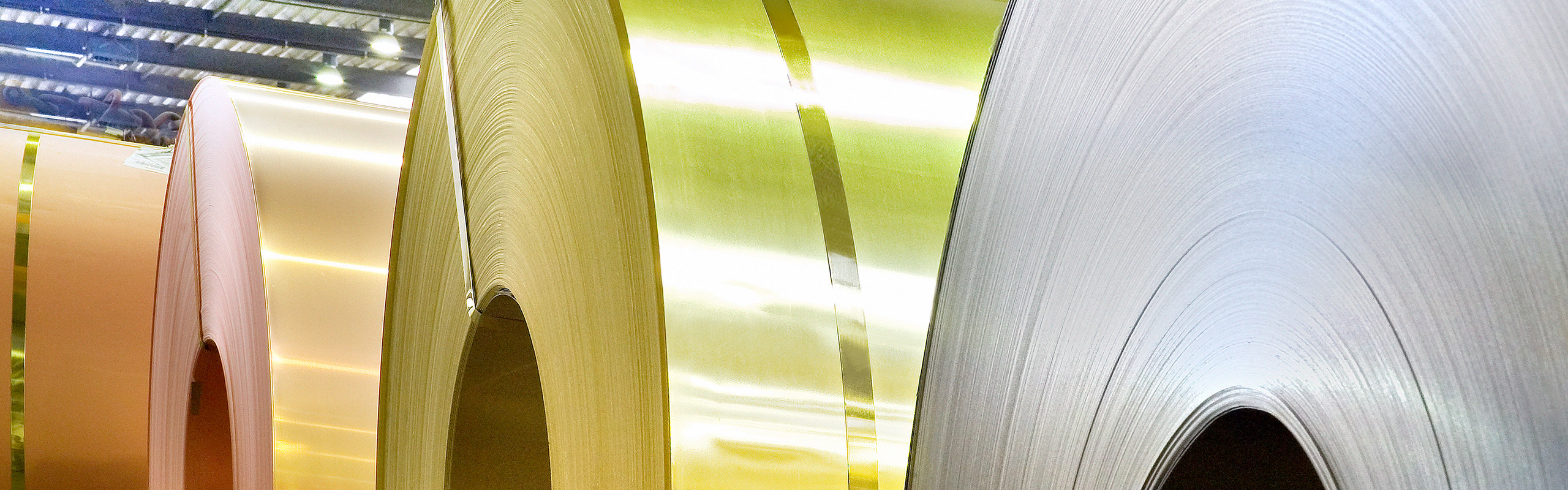

With our electroplating broadband finishing systems, with the most modern machine technology, we achieve highly functional surfaces with copper, brass, nickel and narrowband finishing with zinc. Our brass-plated strips (BRAFIN®) have excellent formability and surface and meet the highest quality requirements in many areas of industry as well as in the decorative sector.

Our nickel-plated strips (NIFIN®) are characterized by a robust and conductive technical surface. The product is used particularly in the electrical industry, filing technology, in the decorative area and for many other industrial requirements for the production of high-quality end products.

Our copper-plated strips (COFIN®) also have excellent properties for forming. Copper-plated tape is particularly characterized by its good conductivity. In addition to its technical properties, the copper layer also acts as a lubricant for forming for sophisticated products. Especially in the electrical and automotive industries.

We have developed EMONI® through constant innovation with regard to the further development of our company and our products. As a nickel-plated material, this new product is an important component in battery systems for e-mobility and other industrial applications.

Up to 80kg of CO2 can be saved per ton of steel if a non-diffusion annealed steel such as "EMONI®" is used for the cell connection.

Our products SELFIN® (selective finishing), MULTIFIN® (multi-layer finishing) and NAFIN® (narrow strip galvanizing) seamlessly join the product family.

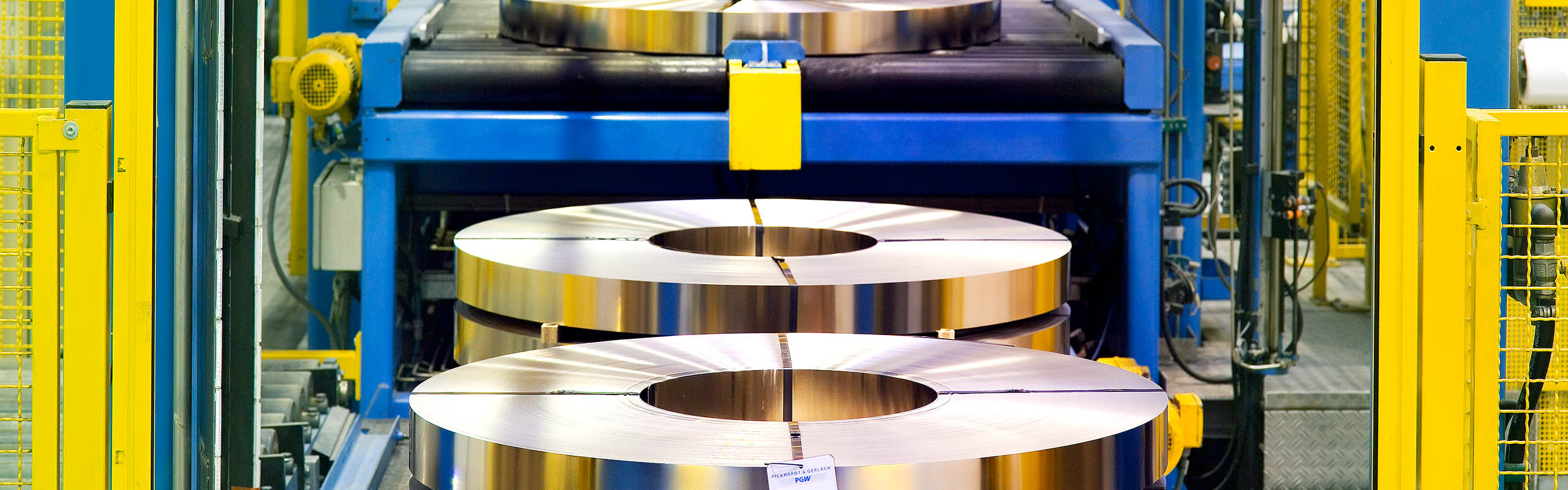

In addition to the precise slitting of the products to customer size and the assembly of the

goods with high-quality packaging, we offer extensive processing in the form of spools, polishing,

painting and foiling. Our customer orientation, our logistics concepts and our high delivery

reliability lead to permanently satisfied customers.

See for yourself.